FABRICATION

HIGH CAPACITY RIGGER FORKLIFTS & HEAVY MACHINERY MOVER CARTS

DAVISON FACILITY

95,000 Square Feet

4416 North State Road -- Davison, Michigan

Bristol Manufacturing was started in 1982 as a division of Bristol Steel, and was tasked with the re-manufacturing of high capacity rigger forklifts and fabrication of heavy machinery mover carts. Due to the unavailability of such equipment, other companies started renting and buying this equipment, thus a new business was formed.

In 1998, Bristol Manufacturing was incorporated and is currently the industry leader in high capacity equipment and builds as many as 60 units in a given year! A few examples of what we produce:

Mini Rigger Special

30,000 lb. Capacity

94" High X 144" Long X 56" Wide

96" Wheel Base

Unmatched Versatility

Rigger Special 60

60,000 lb. Capacity

96" High X 186" Long X 86" Wide (stock)

Long/Short Wheel Base available

Built to specification

Rigger Special 80-100

60,000-100,000 lb. Capacity

106" High X 199" Long X 96" Wide (stock)

Long/Short Wheel Base available

Built to specification

OUR CREDENTIALS

- Member of the SCRA (Specialized Carriers & Riggers Association)

- Member of the BBB (Better Business Bureau)

- Member of the Richfield Twp. & Davison Chambers of Commerce

- Bristol Manufacturing is fully licensed and insured

Angle Master

Our fabricating facility is equipped with the latest state of the art CNC plant equipment.

Equipped with a Peddinghaus Angle Line our shop downloads data directly from our CAD system to ensure accuracy and efficient production time, reducing end costs to our clients.

Our Computer controlled drill line accepts any AISC standard beam shape.

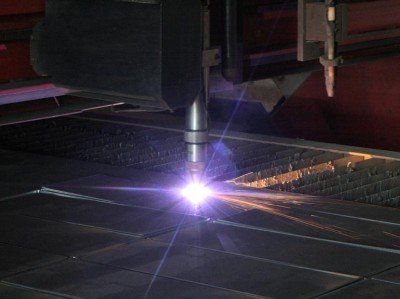

Burn table

Our primary manufacturing facility is equipped with an automated burn table. By matching each piece perfectly with engineered drawings, we improve overall component quality and significantly reduce fit ups, rework and manufacturing costs.

Drill Line

Our facility is equipped with a computer controlled drill machine.

The drill machines ensure quality fit up and layout errors.

Through automation like this we have reduced error throughout our manufacturing process.

General Automation

Our Facility is designed and laid out to automate material processing.

Conveyors bring raw material in from our expansive yard. Once within the facility members are cut using automated band saws.

General Fabrication

After the blasted finish is evaluated and approved the material will move into fabrication.

All fabrication is approved, and prints and quality are verified prior to movement from fabrication station.

All of our welders have undergone numerous hours of training and are AWS certified; and all critical welds are visually inspected and made available for further ultrasound testing if required.

Paint Fabrication

Once the material and assembly has passed the quality inspection, they are moved into the paint bays for finish using the overhead cranes present in each bay. Paint is applied per the customer specifications and the Paint Manufacturer’s recommendations.

The material is loaded onto Bristol’s Transportation Assets or Common Carrier, dependent upon job requirements, and delivered to site for erection.

Browse Our Website

Contact Information

Phone: (810) 658 9510

Toll Free:

(800) 858 9784

Fax:

810-653-5749

Email: MPayne@BristolSteel.com

Address:

4416 North State Road Davison, Michigan48423

Click here

for Bristol Manufacturing

Our Location

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy